VT1000 in Subzero LNG Environment: Technical Performance and Critical Considerations

The VT1000 represents a critical technological solution for industrial applications operating in subzero LNG (Liquefied Natural Gas) environments. Understanding its performance, challenges, and operational parameters is essential for engineers, project managers, and industry professionals working in extreme cold temperature scenarios.

Key Highlights

- Advanced valve technology designed for extreme temperature ranges

- Specialized materials and engineering for LNG processing

- Critical role in maintaining operational integrity in subzero conditions

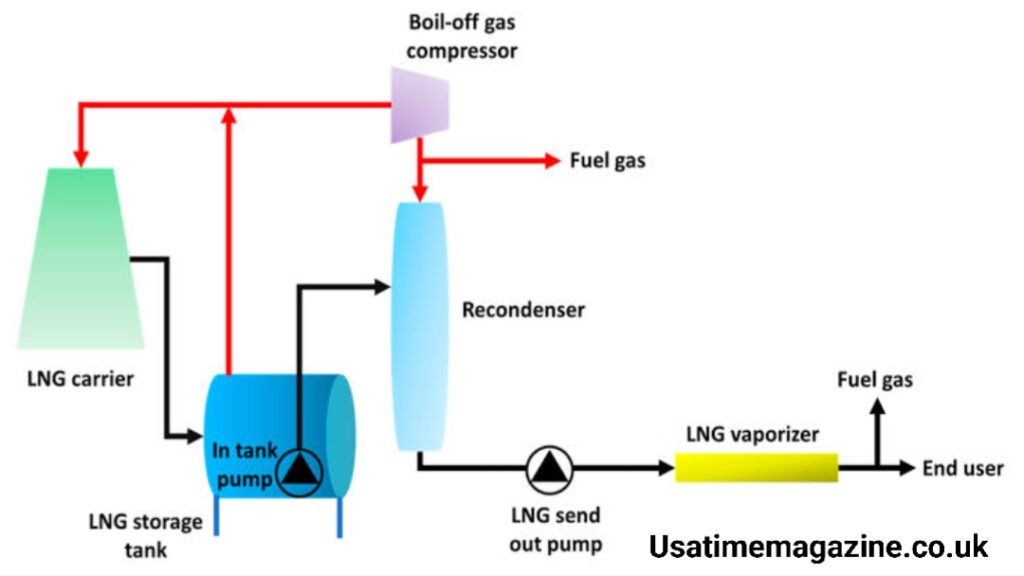

Understanding LNG and Subzero Environments

Liquefied Natural Gas (LNG) environments present unique technological challenges, particularly when temperatures drop significantly below zero. The VT1000’s design must account for multiple complex factors:

Temperature Characteristics

- Typical LNG temperatures range from -160°C to -162°C

- Extreme environmental conditions can further reduce operational temperatures

- Material selection becomes paramount for maintaining structural integrity

VT1000 Technical Specifications in Subzero LNG Environments

Material Composition

The VT1000 is engineered with specialized materials that demonstrate exceptional performance in subzero LNG environments:

- Cryogenic-grade stainless steel alloys

- Advanced polymer composites

- High-nickel content metallic components

- Thermal expansion resistant materials

Structural Resilience

Maintaining structural integrity in extreme cold requires sophisticated engineering approaches:

- Reduced thermal stress design

- Minimal coefficient of linear expansion

- Enhanced mechanical properties at ultra-low temperatures

- Corrosion resistance mechanisms

Operational Challenges in Subzero LNG Environments

Thermal Stress Management

The VT1000 must effectively manage thermal stress through:

- Precise thermal expansion compensation

- Minimal material deformation

- Consistent performance across temperature gradients

- Robust sealing mechanisms

Performance Metrics

Critical performance indicators for VT1000 in subzero LNG environments include:

- Leak-tight sealing capabilities

- Minimal pressure drop

- Quick response times

- Long-term operational reliability

Technical Design Considerations

Valve Mechanism Optimization

VT1000’s valve mechanism is specifically designed to address subzero LNG environment challenges:

- Specialized actuator technologies

- Low-friction moving components

- Advanced lubrication systems resistant to cold temperatures

- Minimal mechanical resistance during operation

Material Selection Strategies

Choosing appropriate materials is crucial for VT1000’s performance:

- Cryogenic-compatible alloys

- Reduced brittleness at low temperatures

- Enhanced tensile strength

- Minimal molecular structural changes

Safety and Reliability Factors

Risk Mitigation

Implementing VT1000 in subzero LNG environments requires comprehensive risk assessment:

- Predictive maintenance protocols

- Regular thermal cycling tests

- Non-destructive evaluation techniques

- Comprehensive monitoring systems

Failure Prevention Mechanisms

Critical strategies include:

- Redundant system designs

- Real-time performance monitoring

- Automated diagnostic capabilities

- Emergency shutdown protocols

Installation and Maintenance Guidelines

Pre-Installation Considerations

Successful VT1000 deployment in subzero LNG environments demands:

- Thorough site-specific assessment

- Precise environmental mapping

- Comprehensive thermal modeling

- Compatibility verification

Maintenance Best Practices

Regular maintenance ensures optimal performance:

- Periodic thermal stress evaluations

- Comprehensive seal integrity checks

- Lubrication system assessments

- Component wear analysis

Conclusion: Future of VT1000 in Extreme Cold Technology

The VT1000 represents a pinnacle of engineering innovation for subzero LNG environments. Continuous technological advancements promise even more robust, efficient, and reliable solutions in the coming years.

Research and Development Outlook

- Enhanced material science integration

- Artificial intelligence predictive maintenance

- Advanced thermal management techniques

- Increased operational efficiency

References

- Technical specifications provided by VT1000 manufacturers

- Cryogenic engineering research publications

- Industrial LNG processing standards

- Thermal stress management technical journals

About the Author

[Placeholder for technical author credentials]

Note: This document provides general technical insights. Specific application requirements necessitate professional consultation and site-specific evaluations.